Whilst burgeoning population and rapid urbanisation are a reality, one big challenge with urban sanitation is to deal with faecal sludge management in environmentally compatible manner. Sewers only serve 25 % of the world population living in urban areas and it has a high maintenance and operational costs. Dr Bindeshwar Pathak developed Sulabh biogas technology – an innovation that converts fecal waste into a resource on-site by turning it into bio-energy and bio-fertiliser.

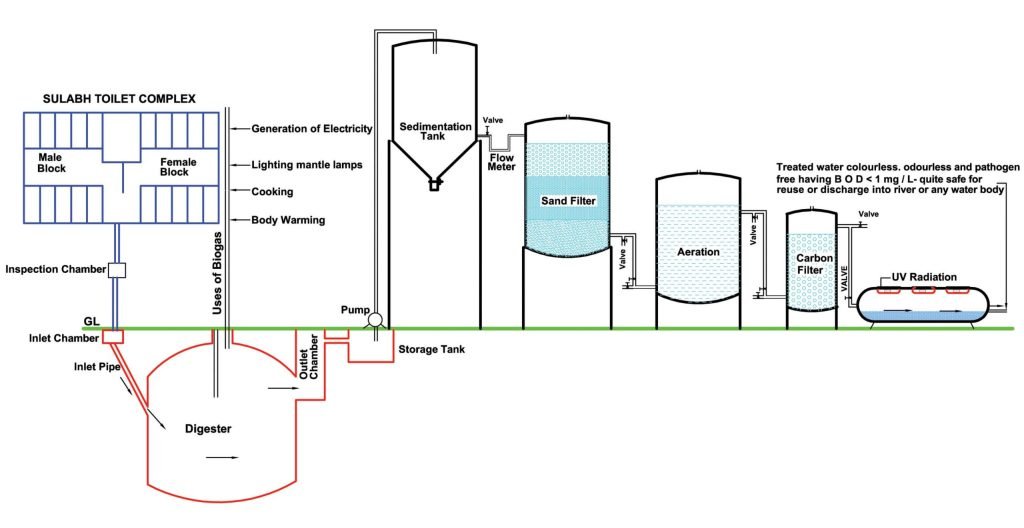

Methodology of Community Toilet Linked Biogas Plant

It is a special system in which human excreta from the Sulabh public toilets goes through the biogas digester. When decomposition takes place it produces biogas. Inside the digester biogas is produced due to anaerobic fermentation by the help of methanogenic bacteria. The biogas, thus produced, is stored inside the digester with an inbuilt liquid displacement chamber.

Sulabh has constructed about 190 biogas plants linked with public toilets installed all over the country. It has also constructed 5 such public toilets with biogas digester in Kabul, Afghanistan and they are functioning very well. In 2007 the temperature went down to –30 degree Celsius and all the complexes worked very well despite the harsh winter.

Merits

- Recycling and reuse of human excreta for biogas generation is an important way to get rid of health hazards from human excreta.

- The Digester is built underground into which excreta from public toilets flows under gravity.

- One cubic foot biogas is produced on an average from human excreta per person per day.

- Biogas is utilised for cooking, lighting through mantle lamps, electricity generation and body warming during winter. Cooking is the most efficient use of biogas.

Human excreta based biogas contains 65-66% methane, 32-34% carbon dioxide and, rest the hydrogen sulphide and other gases in traces + moisture.

Methane is the only combustible constituent, which is utilized in different forms of energy. Its calorific value is 24 MJ/cum or about 5000 Kcal/cum. A one thousand cft. (30 cum) of biogas is equivalent to 600 cft. of natural gas, 6.4 gallons of butane, 5.2 gallons of gasoline or 4.6 gallons of diesel oil.

Biogas burners are available in a wide ranging capacity from 8 cft to 100 cft biogas consumption per hour. It burns with a blue flame without soot and odour. The biogas mantle lamp consumes 2-3 cft per hour having illumination capacity equivalent to 40 W electric bulbs at 220 volt. Motive power can be generated by using biogas in dual fuel internal combustion (IC) engine.

In the last 14-15 years, the IC engines have been mostly replaced by biogas engines, which do not need diesel as a support fuel. These are more dependable in terms of performance. The dual-fuel engines uncertainty about diesel consumption.

The effluent from human excreta based biogas plant has the potential to be used as fertilizer, as it contains a good percentage of nitrogen, potassium and phosphate. But simultaneously its unpleasant odour and presence of pathogens, and high BOD content limit its use for agricultural/horticultural purposes or for direct discharge into a water body.

After a series of experiments, the organization has developed a convenient technology by which the effluent of human excreta based biogas plant turns into a colourless, odourless and pathogen-free liquid manure with BOD of 10 mg / liter or less.

The technology is based on a series of intervention – aeration, sedimentation, sand filter, activated carbon filter and finally, UV radiation (minimum 30 seconds exposure). The SET unit makes it colourless, odourless and free from organic particles and the UV eliminates the bacteria. It reduces BOD and COD of the waste water drastically within the prescribed limit. This is all the more important because the waste water is generated from a public toilet.The SET treated effluent is safe for aquaculture, agriculture, gardening or for discharge into a water body. It can also be used for floor cleaning of public toilets in drought prone areas.

Cost of collection of sewage, operation & maintenance of the sewage treatment plant are avoided.

- No manual handling of human excreta is required.

- It is aesthetically and socially accepted.

- Biogas is used for different purposes.

- Treated effluent is safe to reuse for agriculture, gardening, or discharge into any water body.

- In drought prone areas treated effluent can be used for cleaning floors of public toilets.

If discharged into the sewer, the additional pollution load on STP will be negligible.

Thus, the decentralized system of sewage treatment through biogas technology is more effective for minimizing financial burden to combat pollution.