• Why two-pits are better than one pit?

Single leach Pits are appropriate only if they can be Desludged Mechanically by a Vacuum Tanker since its contents are not pathogen-free. In Two-Pit System, since one pit is used at a time, the filled up pit can be cleaned manually even by the householder himself because of the long period of digestion which makes it free of foul smell and safe for handling.

In the Single Pit System, desludging has to be done almost immediately after the pit has been filled to enable its reuse; this involves the handling of fresh and undigested excreta which is health hazardous.

If a deeper and larger single pit is provided, the desludging operation will be difficult and there would be more chances of pollution especially where the groundwater table is high.

• Fixing of pan & trap

Squatting pan of design specified for pour-flush and trap with 20mm water seal should be used in Sulabh Toilets. The Pan can be of Ceramic, Fibre Glass, PVC, mosaic or Cement Concrete. With Fibre Glass Pan, Traps of HDPE are used. With Ceramic and PVC Pans, Traps of the same material are used. For Mosaic and Cement Concrete Pans, Traps are of Cement Concrete.

To ensure 20mm Water seal, the Trap should be fixed keeping the Top of Inlet and Top Curvature of the Trap Horizontal and the fixing the Pan over it keeping its Rim Horizontal and Flush with the floor.

• Shape of Two-Pits

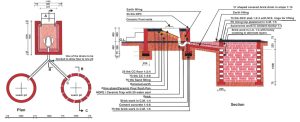

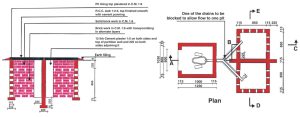

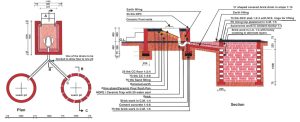

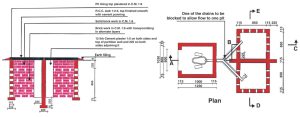

As far as possible, separate Circular Pits should be constructed as these are structurally more stable and the sludge is dry and safe to handle. Where separate Circular Pits of standard sizes can not be constructed due to space constraints, Pits of Smaller Diameter (not less than 750mm) be provided, but Depth should be Increased suitably to provide required Storage Volume and Infiltration Surface Area. If it is not possible to construct Small Diameter Pits, Combined Oval, Square or Rectangular Pits divided into Two Equal Compartments by a Partition Wall be provided. The Partition Wall should be taken 300mm Below the Bottom of the pit and be Plastered on Both Sides with Cement Mortar of 1:6 ratio. The Partition Wall and Pit Lining in 300mm width adjoining the Partition Wall should not have Holes. (See Drawing No. 2). However, the possibility of Water from One Pit finding its way to the other pit is very much there. Therefore the desludging of the filled up pit has to be done with care to avoid health hazards.

• Spacing between Two-Pits

The Minimum Space between the Two-Pits should be One metre or Equal to the Depth of Pits below the level of Incoming Pipe or Drain, whichever is more. Where it is not possible to maintain this space, provide an impervious Barrier like Cut Off Screen or Puddled Wall between the Two-Pits.

• Lining of Pits

The Pits should be lined to avoid collapsing, Lining could be in Brickwork, Stones, Laterite Bricks, Burnt Clay or Cement Concrete Rings. The lining could be done with Treated Bamboos, Wooden Logs, Tar Drums depending upon availability etc.

50mm wide Holes should be provided in Alternate Brick Courses by Laying Bricks 50mm apart. Above the Invert of Incoming Pipes of Drains, No Holes should be provided. Where the Soil is Sandy, Sand Envelope is provided or where there are chances of damage by Field Rats, the width of the Holes should be reduced to 12-15mm.

• Prevention of Pollution

To check Pollution of Drinking Water Sources, the Pits in Fine Soils (Effective Size 0.2mm or Less) should be located at a minimum distance of 3 metres from Open Wells and Shallow Hand Pumps provided Ground Water Table throughout the years is 2 metres or more below the Bottom of Pit; if Water Table is Higher, the distance should be increased to 10 metres. In Coarser Soils (Effective size more than 0.2mm), the Same Safe Distances can be maintained by providing 500mm thick sand Envelope of 0.2mm Sand All round the Pit and Sealing the Pit Bottom by some impervious material like Puddled clay, Polythene Sheet, Lean Cement Concrete stabilised Soil. Normally bacteria do not move beyond 3 metres horizontally in homogenous soil and vertically it does not permeates more than 1 metre, however, there can be marginal deviations depending upon the types and compaction of the soil.

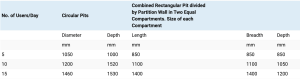

• Size of Pits

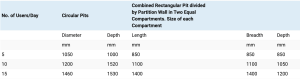

The sizes of Pits where Ground Water Level is always below the Bottom of the Pit and Infiltration Rate of soil is 30 1/m2/day and for 3 years Sludge Storage Volume Works out as follows:

Sulabh Two Pit Toilet Capacity

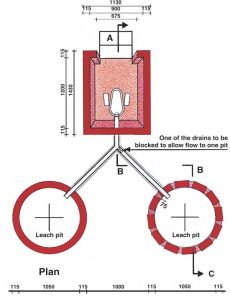

The above depths are from the Invert of Incoming Pipes of Drains to Bottom of Pit. These depths are to be increased by 225mm to provide a free space above the Invert of Pipes/Drains (See Drawings No. 1 and 2).

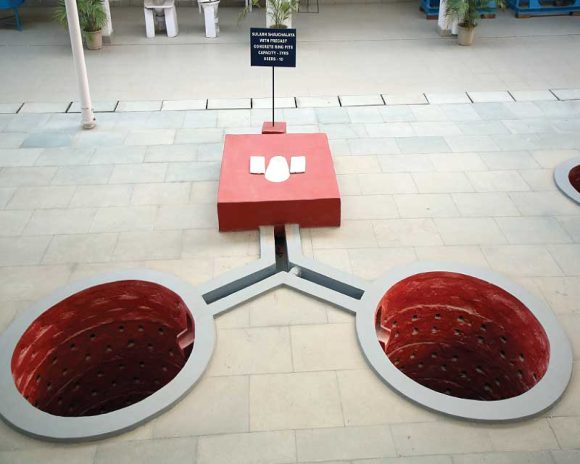

Sulabh Two Pit (Drawing 1)

Sulabh Two Pit (Drawing 2)

8. Pits In High Subsoil, Water Logged And Flood Prone Areas

In waterlogged, flood-prone and high subsoil water areas, the Pits should be raised so that the Invert of Pipe or Drain is just above the likely Water Level. The raising of Pits will necessitate raising of Toilet Floor also. Earth should be filled and well Compacted all around the Pit.

Interconnection between trap and pits

The Trap should be connected to Leach Pits either through ‘U’ Shape Covered Brick Drains of 75mm dia AC or PVC non pressure pipes. In case pipes are used, a Junction Chamber (250mm x 500mm internal size) should be constructed at the place from where the Pipe is Bifurcated to connect the Two-Pits. The pipes of Drains should have a Minimum Gradient of 1:15.